Plot No: 1, Vaigai Industrial Park,

Ayyankottai, Thanichiyam Post,

Madurai - 625 221.

Dipped cords made of Polyester & Aramid yarns can be manufactured in various constructions and finishes. Our cords are made of High Modulus & Low Shrinkage yarns to ensure the power transmission belts maintain their dimensional stability when being subjected to high working stresses, over prolonged periods of time. Our proprietary dip solutions provide an excellent adhesion of the yarn to various kinds of rubber substrates including NR, CR, SBR, CSM, EPDM etc. Write to us at sales@hpcords.com for more information.

| Description | Parameters | Remark |

|---|---|---|

| RAW Materials | Polyester, Aramid | Other specific raw materials can be utilised if required by the customer |

| Linear mass density (Denier) | 3000-59,400 | CCords of higher or Lower deniers can be produced as per requirement. |

| Construction | 1×3, 2×3, 2×5, 3×3, 5×3, 6×3, 5×4, 9×3, 3x4x3, 9×5, 9×6 | Customisable as per requirement |

| Stiffness & Finish | Ultra-soft, soft, semi-stiff, stiff, superior stiff | Customisable as per requirement |

| Dip Solution Compatibility | EPDM, NR, CR, CSM, SBR | Solutions of particular chemical compostions/soild concentrations can be prepared, as per customer |

| Physical properties | Breaking Strength, Elongation, EASL, Free Heat Shrinkage, Adhesion, Cord Gauge, Weight/meter | Our dipped cords match all these specifications given by our customers |

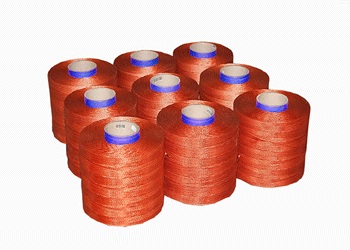

| Packing | Metal bobbins, 8-13 kgs per bobbin, Cardboard tubes, 0.8 – 10 kgs per tube. | Can be parallel wound on flat or conical tubes of dimensions specified by the customer |